Pressure testing applications include various applications such as autofrettage, cycle/fatigue testing, hydrostatic testing, impulse testing, and leak testing. These are divided into two main sections, gas pressure testing and liquid pressure testing.

Liquid applications range in pressures from 10,000 to 200,000 psig (69 to 1400 MPa). Process fluids include non-corrosive (hydraulic oil, water). These include autofrettage, cycle/fatigue testing, hydrostatic testing and impulse testing.

For gas applications, Hydro-Pac manufactures equipment for standard pressure ranges of 1,500 to 60,000 psig with gases that include Argon, Carbon Dioxide (CO2), Compressed Natural Gas (CNG), Helium, Hydrogen, Methane, Nitrogen and mixtures of these gases. Gas compressors can also be provided for ultra-high pressures up to 175,000 psig and speciality gases.

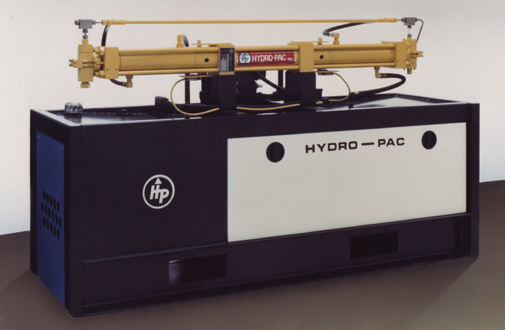

PRESSURE TESTING:

FEATURES

- Gas compressors used for testing applications up to 175,000 psig (1207 MPa) and liquid pumps used for applications up to 200,000 psig (1400 MPa).

- All pumps and compressors are electro-hydraulically driven intensifier machines.

- Utilizing various options with the hydraulic drive allows precise control of pressurization rates and accuracy.

- Hydro-Pac can offer custom systems for any of the equipment below to meet requirements from ultra high-pressure applications to lower-pressure high-capacity applications.

- Hydro-Pac can offer turn-key solutions that •include PLC controls, valve racks, vessels, enclosures as well as ancillary equipment such as burst chambers or containerized packages.

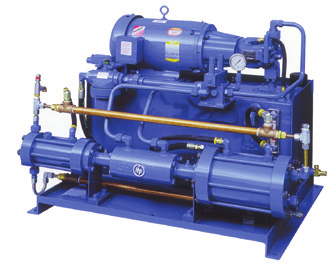

GAS PRESSURE TESTING

- Standard operating ranges for this line are:

- Discharge pressures: 10,000 to 60,000 psig (69 to 414 MPa)

- Inlet pressure range: 500 to 3,000 psig

- Capacity ranges: 5 scfm to >300 scfm

- The FLEXI-POWER compressor is ideal for ultra-high pressure high pressure and large capacity applications. The FLEXI-POWER line includes special machines for up to 120,000 psig maximum working pressure

- Standard operating ranges for this line are:

- Discharge pressures: 1,000 to 12,000 psig

- Inlet pressure range: 70 to 6,000 psig

- Capacity ranges: <1 scfm to >300 scfm

- The LX-SERIES compressor can be used for heavy duty low-pressure applications or gas scavenging (reclaim) application to use all of the available gas in the cylinders.

- Standard discharge pressures: 10,000 to 30,000 psig

- Standard ID: 6 to 52 inches (152 to 1321 mm)

- Closure types: Full thread, breach thread (quarter turn) and pin.

- Designs: Monobloc, Tie-rod, Multi-Wall and other special designs.

- Codes: ASME Section VIII, Division 1, 2, or 3; PED (Europe);KHK (Japan); or non-code designs.

- Machined from forgings or bar stock.

- Speciality vessel designs.

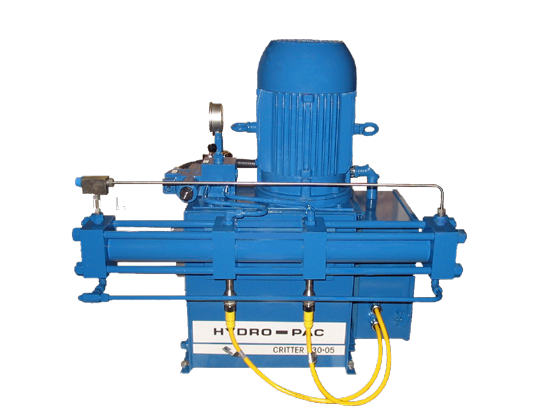

LIQUID PRESSURE TESTING

- Standard operating ranges for this line are:

- Discharge pressures: 10,000 to 200,000 psig (70 to 1400 MPa)

- Frame sizes: 10 to 200 HP (7.5 to 150 kW)

- Non-corrosive fluids with options for water and other fluids.

- The FC-SERIES pumps are production class units and is ideal for high pressure, larger flowrate applications.