As an alternative to pyrotechnic inflators, stored gas inflators rely on compressed gas to deploy the inflator. Depending upon the deisgn these inflators will use Argon, Helium, Nitrogen or a mixture of these gases. In response to demand Hydro-Pac has developed a complete system to cleanly compress the gas while providing a dependable operation.

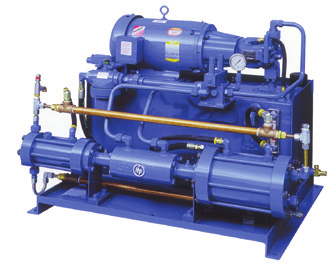

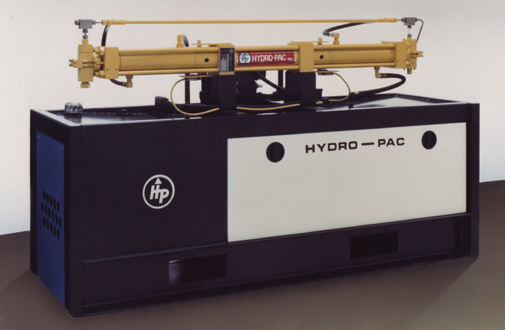

Our system design is developed primarily around our LX-SERIES™ and FLEXI-POWER™ Gas Compressors. These compressors are used in series to boost the gas to pressures from 10,000 to 20,000 psig from standard inlet storage pressures. The system combines these compressors into a single package that includes the required valves, monitors, piping, PLC controls and base platform to provide a near turn key system. This design simplifies installation and reduces start-up time.

AIRBAG INFLATOR FILLING

FEATURES

- Oil-free non-lubricated gas pistons and protect against oil contamination of the process gas.

- Full stroke-length distance pieces isolate the hydraulic drive from the gas cylinders. This prevents contamination of the gas by the hydraulic drive oil.

- Hydro-Pac gas compressors work over a wide range of inlet pressures. In many cases inlet pressure regulators are not required.

- Intensifiers are ideally suited for high pressures due to the simple geometry, slow operating speeds and in-line loads.

- Long slow stroke and small dead volume in the compressor cylinders result in high volumetric efficiency.

- Water cooled gas cylinders lower operating temperatures, which increases packing life.

- Hydraulically driven intensifiers allow control of both discharge pressure and gas flow rate by controlling the hydraulic drive. This may be important when matching the flow rate of the compressor to that of a reformer or electrolyzer.

- Straightforward arrangement and patented free piston design of Hydro-Pac compressors simplifies maintenance.

- Gas pressure assists in the compression stroke improving the overall efficiency of the machine.

- Standard operating ranges for this line are:

- Discharge pressures: 1,000 to 12,000 psig

- Inlet pressure range: 70 to 6,000 psig

- Capacity ranges: <1 scfm to >300 scfm

- This model is used as the low pressure compressor to boost the storage gas to an intermediate pressure. In cases where the discharge pressure is less than 12,000 psig or lower this model will also be used for the high pressure compressor

- Typical discharge pressures: 10,000 to 20,000 psig

- Inlet pressure range: Gas bottles, mixers or cryogenic evaporators.

- Capacity ranges: 5 scfm to >300 scfm

- Typical systems include:

- Turn-key systems.

- PLC controls.

- Gas storage.

- Closed loop cooling.

- Valves, fittings and piping systems.

- Packaged customized compressor systems.