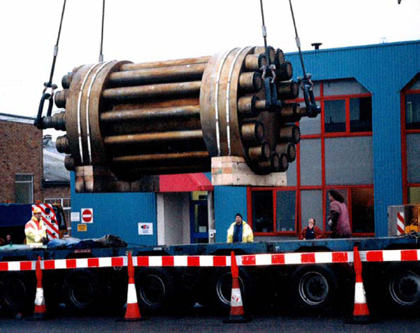

Cold isostatic pressing (C.I.P.) is a high-pressure manufacturing process used to compact metal, plastic, composite or ceramic powders uniformly. C.I.P. parts are enclosed in a flexible, sealed container and immersed in a pressure vessel filled with a liquid at ambient temperature.

Our experience includes manufacturing pumps, valve racks and high-pressure vessels at pressure ranges from 10,000 to 60,000 psig (69 to 414 MPa). The process liquid is typically a non-corrosive water and soluble oil mixture. However some C.I.P. applications, such as food C.I.P. use water. Hydro-Pac pumps can be offered for both non-corrosive fluids and water.

COLD ISOSTATIC PRESSING (C.I.P.)

FEATURES

- Robust, reliable, low-maintenance design.

- FC-SERIES pumps for productions class applications.

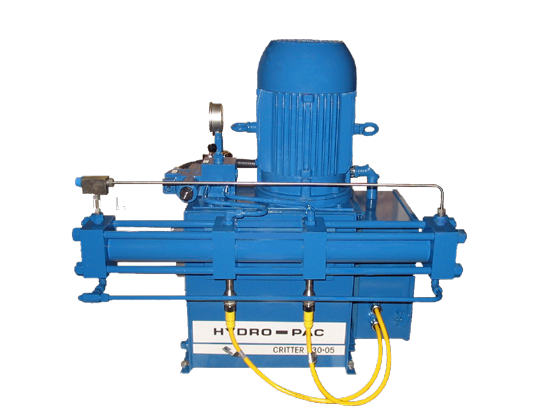

- Li’l Critter™ pumps for laboratory usage and test applications.

- Standard FC-SERIES and Li’l Critter™ pumps are double ended intensifiers with electro-hydraulic power units.

- Double ended pumps are typically used for filling large volumes.

- Single shot pumps used for smaller volumes. Single shot pumps eliminate the requirement and cost of let down valves.

- Custom control and piping systems can be quoted for any machine.

- Standard operating ranges for this line are:

- Discharge pressures: 10,000 to 200,000 psig (70 to 1400 MPa)

- Frame sizes: 10 to 200 HP (7.5 to 150 kW)

- Non-corrosive fluids with options for water and other fluids.

- The FC-SERIES pumps are production class units and is ideal for high pressure, larger flowrate applications.

- Standard discharge pressures: 10,000 to 30,000 psig

- Standard ID: 6 to 52 inches (152 to 1321 mm)

- Closure types: Full thread, breach thread (quarter turn) and pin.

- Designs: Monobloc, Tie-rod, Multi-Wall and other special designs.

- Codes: ASME section VIII, Division 1, 2, or 3; PED (Europe); KHK (Japan); or non-code designs.

- Machined from forgings or bar stock.

- Speciality vessel designs